Cutting Glass Clean using a Specialized Glass Cutting Bit

Ah, the age-old struggle of cutting perfect circles in glass. If you've ever tried it, you know it's a task that can make even the most patient hobbyist want to pull their hair out. But what if we could delegate this intricate task to our trusty robots? Enter the CNC machine with a custom-made glass cutter bit.

For those interested in a deeper dive into the intricacies of milling glass, check out our previous post on Milling Glass: A Comprehensive Guide to Precision and Safety.

Milling glass is no walk in the park! Its inherent brittleness can lead to unexpected cracks, while its lack of ductility makes fine detailing a nail-biting affair. Add to that the rapid wear of tools (even those fancy diamond-tipped ones), the pesky heat generation causing potential deformities, and the ever-present challenge of holding the glass just right without it going "Oops! I broke again." And let's not even get started on the safety hazards of sharp edges and inhaling fine glass dust. It's enough to make any hobbyist consider taking up knitting instead! But hey, where's the fun without a challenge, right?

The inspiration for this Clough42 project came from a pile of imperfectly cut glass circles, a testament to the challenges of manually cutting precise glass circles. The traditional glass circle cutter, while simple in design, has its limitations. The manual cutter's inaccuracy stems from the looseness in its joints, leading to inconsistent circle dimensions. This realization sparked the idea of creating a CNC-compatible tool that could potentially offer more precision.

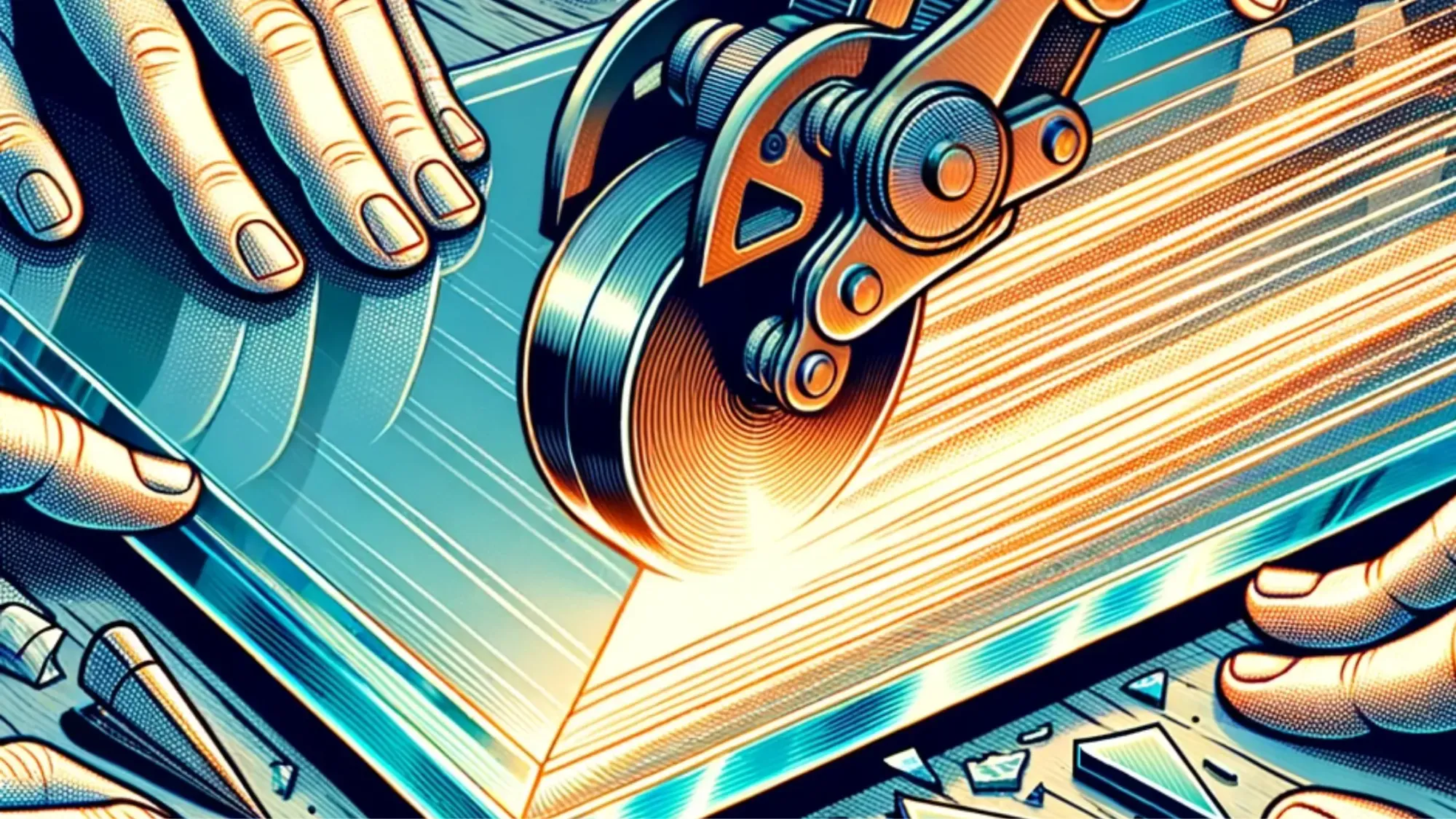

Clough42 tackles the age-old woes of glass milling with a nifty CNC twist. Ditching the traditional, often frustrating milling methods, our savvy creator scores the glass using a repurposed swivel blade, giving a big thumbs down to unexpected cracks and tool wear. With the CNC's precision, vibrations are a thing of the past, and those pesky heat issues? A few drops of oil do the trick. And let's give a shoutout to those 3D-printed clamps holding the glass just right. It's innovation on a budget, making glasswork feel less like a treacherous tightrope walk and more like a smooth waltz. Talk about a game-changer! 😉

Creating the CNC-compatible glass cutter bit, as showcased by Clough42, requires a blend of materials and some crafty engineering. At the heart of the tool is a block made from tool steel, shaped meticulously using a lathe. This block is designed to house a swivel blade, which is cleverly repurposed from a manual glass circle cutter. To ensure a snug fit and precise movement, the block is flattened using a mill and drilled to accommodate set screws. The cherry on top? A spring-loaded mechanism that controls the blade's pressure, ensuring the glass is scored without excessive force.

When it comes to the actual cutting process, precision is the name of the game. The tool is fitted into a CNC machine, ready to dance across the glass surface. But before it takes its first step, a few drops of oil are applied to the glass. This lubrication reduces friction, allowing the blade to glide smoothly and score the glass with finesse. With this tool in hand, the challenges of traditional glass milling seem like a distant memory.

Merging old-school charm with techy smarts, this tool laughs in the face of traditional milling challenges. It's a cheeky nod to innovation, proving that with a sprinkle of creativity and some CNC magic, glasswork can be a breeze. So, gear up, fellow CNC enthusiasts; glasswork's got a fun twist, and it's time to join the party! 🎉🛠️