A Guide to Selecting Materials for Your Home-Made CNC Frame

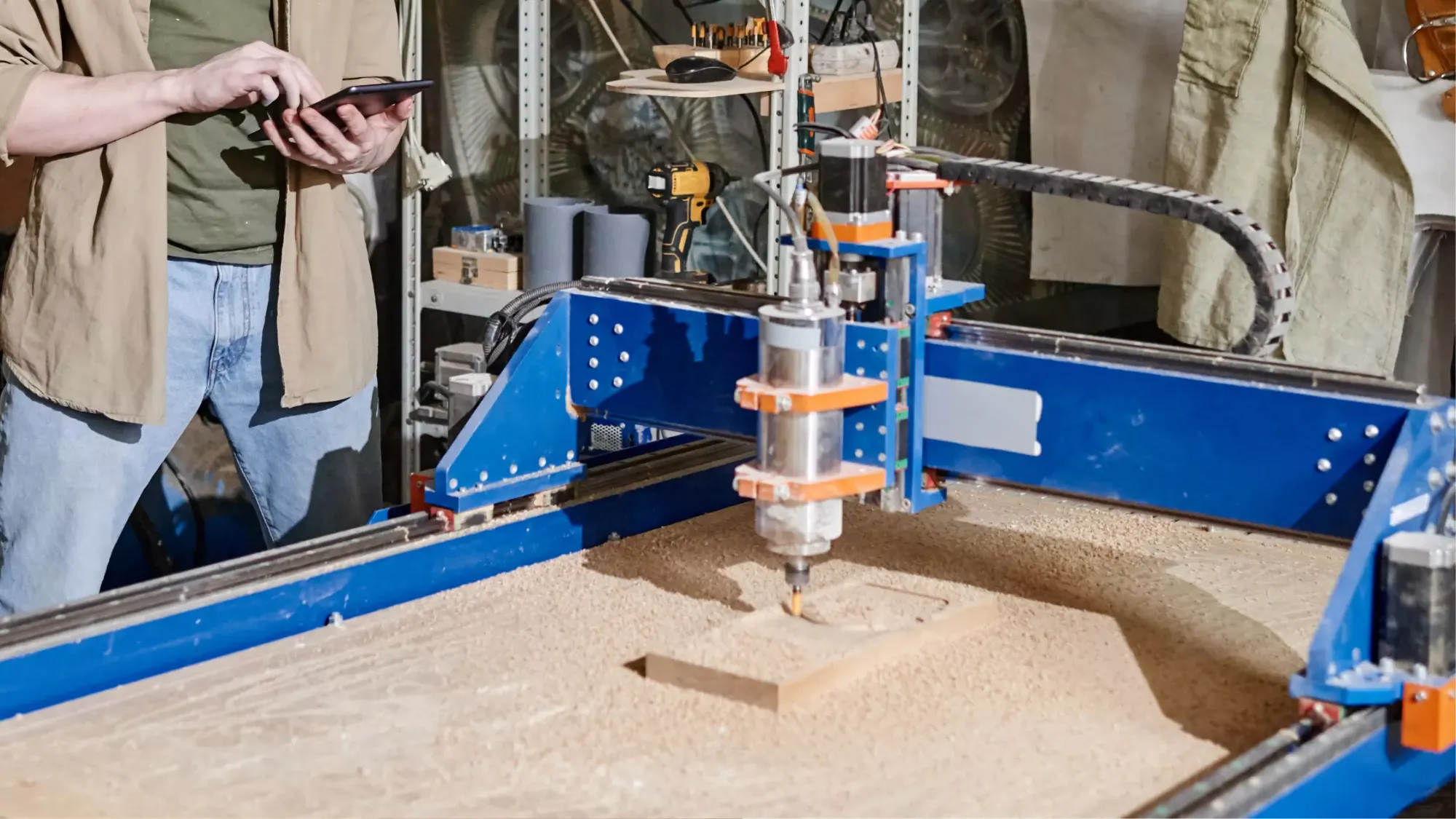

Building a CNC machine at home is an exhilarating journey into the world of DIY craftsmanship. For many, it's a blend of engineering curiosity and the desire to create something tangible with precision. As you embark on this adventure, you'll find that there are numerous decisions to make, each impacting the final outcome of your project.

One of the most pivotal choices lies in selecting the right material for the machine frame. This isn't just about aesthetics or cost; it's about the very foundation of your CNC machine. The frame is its backbone, providing the structural integrity needed for accurate operations. The material you choose will influence the machine's durability, precision, and overall performance, especially when considering the diverse materials the machine will work on.

Why does the Frame Material Matter?

The frame of a CNC machine is much like the skeleton in the human body; it provides structure, and support, and determines the overall functionality and efficiency of the machine.

Stability and Vibration Reduction:

- Importance: A stable frame is essential for achieving precise cuts and engravings. Any slight vibration can lead to errors, especially when working on detailed projects.

- Impact: Materials that absorb vibrations or are inherently stable can drastically improve the machine's accuracy.

Durability and Longevity:

- Importance: A CNC machine is an investment. The frame material's durability directly affects how long the machine will last and how well it will withstand regular use.

- Impact: Stronger materials can handle wear and tear, ensuring that the machine remains functional for years if not decades.

Cost-Effectiveness:

- Importance: While it's tempting to go for the cheapest option, it's essential to consider the long-term costs. A material that wears out quickly might require replacements or repairs, leading to higher expenses over time.

- Impact: Materials that offer a balance between initial cost and longevity provide the best value for money.

Weight and Portability:

- Importance: The weight of the frame material affects the machine's portability and the stability of its base. A too-light frame might move during operations, while a too-heavy one might be challenging to relocate.

- Impact: Choosing a material with an optimal weight ensures that the machine remains both stable during operations and relatively easy to move when necessary.

Compatibility with Target Working Materials:

- Importance: The frame material should complement the materials the CNC machine will work on. For instance, a frame suitable for woodworking might not be ideal for metalwork.

- Impact: A frame that's compatible with the target materials ensures efficient operations without undue stress on the machine.

Thermal and Environmental Resistance:

- Importance: CNC operations can generate heat. The frame material should resist warping or degradation due to temperature changes. Additionally, it should withstand environmental factors like humidity.

- Impact: Materials resistant to thermal and environmental changes ensure consistent performance and reduce maintenance needs.

The frame material doesn't just hold the machine together; it plays a pivotal role in determining its performance, reliability, and lifespan. Making an informed choice in this aspect lays the foundation for a successful CNC machining experience.

Top Materials for a Home-Made CNC Machine Frame

Selecting the right material for your CNC machine frame is a blend of understanding the material's properties and aligning them with your machining needs. Here's an in-depth look at the top materials commonly used for DIY CNC frames:

MDF (Medium Density Fiberboard):

MDF is an engineered wood product crafted from wood fibers combined under heat and pressure. It's favored for its affordability and ease of use, especially for woodworking projects. However, while it offers a smooth surface ideal for finishes, it lacks the durability of metals and can be susceptible to moisture and warping.

- Composition: Engineered wood products made from wood fibers glued under heat and pressure.

- Best for: Softwoods, plastics, foam.

Pros:

- Affordable and widely available.

- Easy to work with using standard woodworking tools.

- Provides a smooth surface ideal for painting or sealing.

Cons:

- Less durable compared to metals.

- Can warp over time, especially in humid conditions.

- Susceptible to moisture damage if not sealed properly.

Aluminum:

A lightweight yet robust metal, aluminum stands out for its corrosion resistance and malleability. It's an excellent choice for CNC frames due to its good strength-to-weight ratio. While it's pricier than wood-based materials, its resistance to rust and the option for anodization make it a long-lasting option.

- Composition: Lightweight metal known for its corrosion resistance and malleability.

- Best for: Softwoods, hardwoods, plastics, soft metals.

Pros:

- Lightweight yet strong, offering a good strength-to-weight ratio.

- Resistant to rust and corrosion.

- Can be anodized for enhanced durability and aesthetics.

Cons:

- More expensive than wood-based materials.

- Requires specialized tools for cutting and drilling.

Steel:

Steel, an alloy primarily of iron and carbon, is renowned for its high tensile strength. Its extreme durability and ability to handle heavy loads make it ideal for more intensive CNC operations. While offering unmatched rigidity, it's heavier than aluminum and requires protection against rust.

- Composition: Alloy is made primarily of iron and carbon, is known for its high tensile strength.

- Best for: Hardwoods, metals, stone.

Pros:

- Extremely durable and can handle heavy loads.

- Provides excellent rigidity, reducing vibrations.

- Available in various grades, allowing for customization based on needs.

Cons:

- Heavier than aluminum, making it less portable.

- Can rust if not treated or painted.

Plywood:

Constructed from layers of wood veneer pressed together, plywood is both affordable and reasonably strong due to its layered design. It's a versatile choice for lighter CNC tasks, but care must be taken as it can warp in humid conditions and may delaminate under stress.

- Composition: Layers of wood veneer pressed together.

- Best for: Softwoods, foam, plastics.

Pros:

- Affordable and easy to source.

- Offers decent strength due to its layered construction.

- Can be sealed or painted for added durability.

Cons:

- Can warp in humid conditions.

- Layers can delaminate under heavy stress.

Acrylic and PVC:

Synthetic polymers are known for their versatility. Acrylic, often transparent, offers unique design possibilities, while PVC boasts resistance to chemicals and moisture. Both are lightweight and suitable for engraving tasks, but they don't match the durability of metals and can be prone to cracking under pressure.

- Composition: Synthetic polymers are known for their plasticity and versatility.

- Best for: Engravings, light plastics.

Pros:

- Lightweight and easy to work with.

- Transparent acrylic allows for unique design possibilities.

- PVC is resistant to chemicals and moisture.

Cons:

- Less durable than metals.

- Can crack or break under heavy stress.

Each material comes with its unique set of advantages and challenges. When choosing the right one for your CNC machine frame, consider factors like your budget, the machine's intended use, and the environment in which it will operate. The goal is to strike a balance between performance, durability, and cost.

Factors to Consider When Choosing a Material for Your CNC Machine Frame:

Selecting the right material for your CNC machine frame is a critical decision that impacts its performance, durability, and efficiency. It's essential to consider the machine's primary function, the longevity you desire, your budget constraints, and the conditions of your workspace. Additionally, factors like vibration reduction, ease of modification, aesthetics, weight, potential for future upgrades, and environmental impact play a pivotal role in the decision-making process. By weighing these considerations, you can ensure that your CNC machine serves your needs optimally and stands the test of time.

The material you choose for your CNC frame will play a pivotal role in the machine's performance, longevity, and overall user experience.

Intended Use:

The primary function of your CNC machine will significantly influence your material choice. If you're planning to work with metals or harder materials, you'll need a sturdier frame like steel. For softer materials like foam or plastics, MDF or plywood might suffice.

Durability and Longevity:

Consider how long you want your CNC machine to last. Metals like steel and aluminum are more durable and can withstand wear and tear better than wood or acrylic. They're also less susceptible to environmental factors like humidity.

Budget:

Your available budget can narrow down your options. MDF and plywood are generally more affordable than metals. However, investing in a metal frame might save you money in the long run due to its durability.

Work Environment:

If your workshop is prone to moisture or drastic temperature changes, you'll want to choose materials that can withstand these conditions. Steel, for instance, would need rust protection, while MDF would require sealing against moisture.

Vibration and Stability:

CNC machines produce vibrations during operations. Materials like steel offer excellent rigidity, reducing vibrations and ensuring more accurate machining. On the other hand, softer materials might require additional bracing or support.

Ease of Modification:

Depending on your expertise and available tools, some materials might be easier to work with than others. For instance, MDF and plywood can be easily cut and drilled using standard woodworking tools, while metals might require specialized equipment.

Aesthetics:

If the look of your CNC machine matters to you, consider materials that offer a pleasing finish or can be easily painted or modified. Aluminum, for example, can be anodized for both protection and aesthetics.

Weight and Portability:

If you intend to move your CNC machine frequently, a lightweight frame made of aluminum or acrylic might be preferable. Steel, while sturdy, adds significant weight to the structure.

Expansion and Upgrades:

Think about future modifications. If you plan to upgrade or expand your CNC machine, choose a material that can easily accommodate these changes without compromising structural integrity.

Environmental Impact:

Sustainability is a growing concern. If this matters to you, consider materials that are recyclable, like metals, or sourced sustainably, like certain grades of plywood.

The material you choose for your CNC frame will play a pivotal role in the machine's performance, longevity, and overall user experience. It's essential to weigh all these factors carefully to make an informed decision that aligns with your needs and goals.

Wrapping Up

Crafting a homemade CNC machine is not just about assembling parts; it's about understanding the heart and soul of the machine - its frame. The material you choose for this frame will dictate not only the machine's durability but also its efficiency, precision, and overall performance. As we've explored, options range from the affordability of MDF and plywood to the robustness of metals like steel and aluminum. Each material comes with its unique set of advantages and challenges, making it crucial to align your choice with your project's demands, budget, and long-term goals.

As you embark on this exciting journey of building your CNC machine, remember that it's a blend of art and science. While technical factors are paramount, your personal touch, creativity, and vision will breathe life into the machine. Whether you're a hobbyist looking to dabble in DIY projects or an expert aiming for professional-grade work, the right frame material will be your steadfast ally. Here's to building a CNC machine that not only meets but exceeds your expectations!